- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2022-12-01 Origin: Site

Ink-jet printing is a contact-free, pressure-free, print-free printing and reproduction technology. It has the common characteristics of passive digital printing, which can realize variable information printing. The screen printing printing plate is a mesh, and the ink on the printing plate from the plate through the hole part of the plate plate extrusion to the carrier, and then complete the printing method of the printing operation.

一、Introduction of the two printing methods

1.ink jet printing

There are many kinds of inkjet printing way, its basic principle is to input the electronic computer storage of graphic information to the flat printer, and then through a special device, under the control of the electronic computer, by the nozzle to the bearing material surface spray fog-like ink droplets, according to the charge effect on the surface of the bearing material direct image, become the final print.

The basic principle of inkjet printing is to produce small ink droplets first, and then lead to the set position. According to the different inkjet system, can be divided into continuous and on-demand two kinds.

Continuous inkjet printing (CIJ), whether in print or non-print, continuously produces ink droplets in a flowing way, and then forms images through electric field deflecting transfer, and finally the non-print ink droplets are recovered or dispersed. On-demand inkjet printing (DOD) produces ink droplets only in the print section. Dedicated to printing excellent quality images, suitable for printing packaging color drawings, textiles and large face billboards, is the ideal choice for full color, high precision printing, printing quality is its most important consideration.

Inkjet printing according to its printing color, can be divided into black and white inkjet printing and color inkjet printing two kinds. Black and white inkjet printing with a single ink, the machine structure and ink system is also relatively simple, and color inkjet printing is relatively complex.

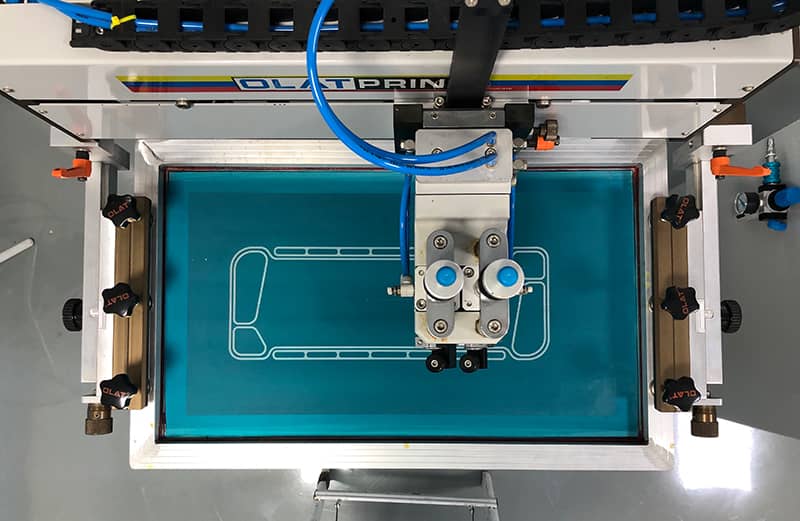

2.Screen printing

Modern screen printing technology is to use photosensitive materials to make the method of screen printing (the screen hole for the screen hole, rather than the graphic part of the screen hole is blocked). When printing, through the extrusion of the scraper, the ink is transferred to the seal through the mesh of the graphic part, forming the same text as the original manuscript.

Screen printing consists of five elements, namely, screen printing plate, scraper scraper, ink, printing table and bearing material. Screen printing equipment is simple, easy to operate, simple printing, plate making and low cost, strong adaptability. There are also many common prints used in a wide range of screen printing, such as color oil paintings, posters, business cards, binding covers, commodity signs, and printing and dyeing textiles.

二、Comparative analysis of the two printing methods

Inkjet printing is another ten thousand new printing technology after screen printing, and screen printing is widely printing materials, can be printed in different shapes, different material surface, strong adaptability, is currently a very rapid technology development, the market is expanding new printing methods, showing great development prospects. However, as an old way of printing, screen printing in the process of development also shows a strong side of aging, especially the unique advantages of screen printing in circuit board printing. In addition, with the application of more and more new technologies in screen printing, screen printing changes new appearance, still occupies the vast market.

1.The competition between the two printing methods

First, there is the competition in the application field and the product market. Based on the advantages of the two printing methods, it is not difficult to find that they are increasingly competitive in the printing market. First of all, some large-scale keyface printing fields compiled by screen printing are being impacted by inkjet printing. Today, the inkjet machine used in the field of large-scale inkjet painting, whose maximum format can reach 3~5m, plays an increasingly prominent role in the production of large-scale posters, publicity materials and outdoor advertising. Secondly, because inkjet printing has relatively small restrictions on the substrate, it can be printed on a variety of substrate materials, which is the killer mace of screen printing compared with other printing methods. Inkjet printing has this advantage, which will undoubtedly have an impact on the application field of screen printing. Thirdly, inkjet printing is a full digital printing, which is completely separated from the cumbersome process of the traditional printing process, and can minimize the marketing time of the product. For those products with high time requirements, this printing method will be the best choice.

Moreover, the competition for the printers of the No. Inkjet printing has its unique market such as lottery printing, personalized printing is screen printing dust, inkjet printing in defending these fields at the same time, their own application to the territory of screen printing, products are gradually favored by the majority of printers. As mentioned above, in the large-scale printing, with the prosperity of the market economy and the expansion of commodity circulation, the inkjet printing of outdoor advertising will show a significant upward trend. The advantages of fully digital inkjet printing, personalized printing and other remote printing, will inevitably attract more printers to adopt it. Therefore, it can be said that while competing in the product market, their competition cannot be separated from the competition for printers.

2.The advantages between the two printing methods are complementary

With two ways, can save production time, improve efficiency. Even if the inkjet printer has full digital, job preparation for a short time, rapid response to the market advantages, but it is not perfect after all, inkjet printing a big disadvantage is not suitable for large quantities of printing, and only suitable for less than 1000 printing, therefore, screen printing in mass printing technology advantage is revealed incisively and vividly. When the personalized printing of product packaging to determine can use this method, namely use the inkjet printing for small batch printing, into the market after research, according to the research results and choose popular design to mass printing, which not only saves the cost, can also reduce the waste and product time to market. The above is just an option, and of course there are other better ways to work.

Home / Products / Why OLAT / Manufacturing / Application / Support / News / Contact Us / privacy policy