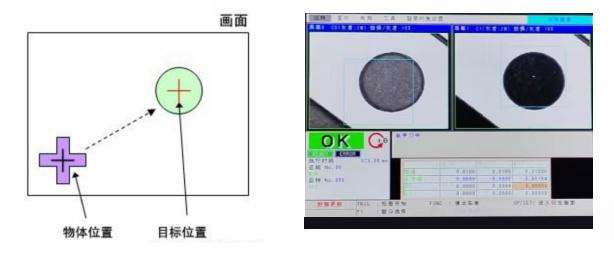

Oriented by customer needs, CCD visual alignment is upgraded again In the thick film printing process of electronic components, the CCD visual alignment system can automatically correct deviations, effectively control errors caused by manual feeding, and improve the yield rate in mass production. It is widely used in high-precision thick film printing.However, due to the complexity of operation and debugging, the requirements for skilled workers are relatively high during production and use.Recently, many old customers have asked whether the operation difficulty can be simplified and the printing accuracy can be improved when they repurchase.In response to these problems, in 2023, we visited a number of customer companies to understand the actual production needs, organized the company's technical team to conduct multiple discussions on the alignment system, and arranged for technical personnel to conduct multiple technical communications with customers.In the end, we ignored the cost investment and cooperated with CCD vision system manufacturers to conduct a large-scale upgrade of the existing software and introduced a new CCD vision alignment system.Introduction to the traditional alignment method: manually align the product with the screen position, then align the visual lens on the product to capture the MARK point

English

English English

English