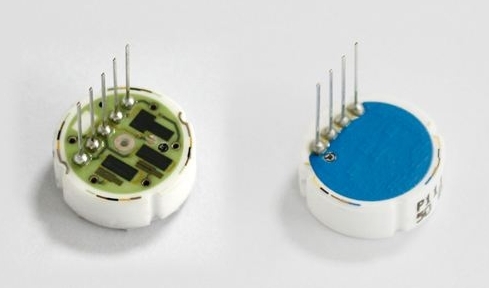

Technical application of high-precision thick film screen printing in ceramic sensors A sensor is a device used to sense and detect physical information and convert it into electrical signals.Due to its advantages of miniaturization, digitization, and intelligence, it is widely used in automobile industry batteries, medical fields (adding blood glucose meter links), environmental testing, aerospace and other application fields.Sensors can be divided into integrated sensors, thin film sensors, thick film sensors, ceramic sensors, etc. according to process classification.Among them, ceramic sensors are sensors made of ceramic materials. Because ceramic materials have the advantages of high sensitivity, good linear response, high temperature resistance, corrosion resistance, and high strength, they have become an ideal material for making ceramic sensors in recent years.In the production process of ceramic sensors, the first step is to process the ceramic materials: ① Sieve the ceramic powder to ensure uniform particles.② Processed into the required shape and size, the most common methods are molding, injection molding, die casting and extrusion.③Drying and sintering, the time and temperature need to be determined according to the ceramic

English

English English

English