- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2024-10-24 Origin: Site

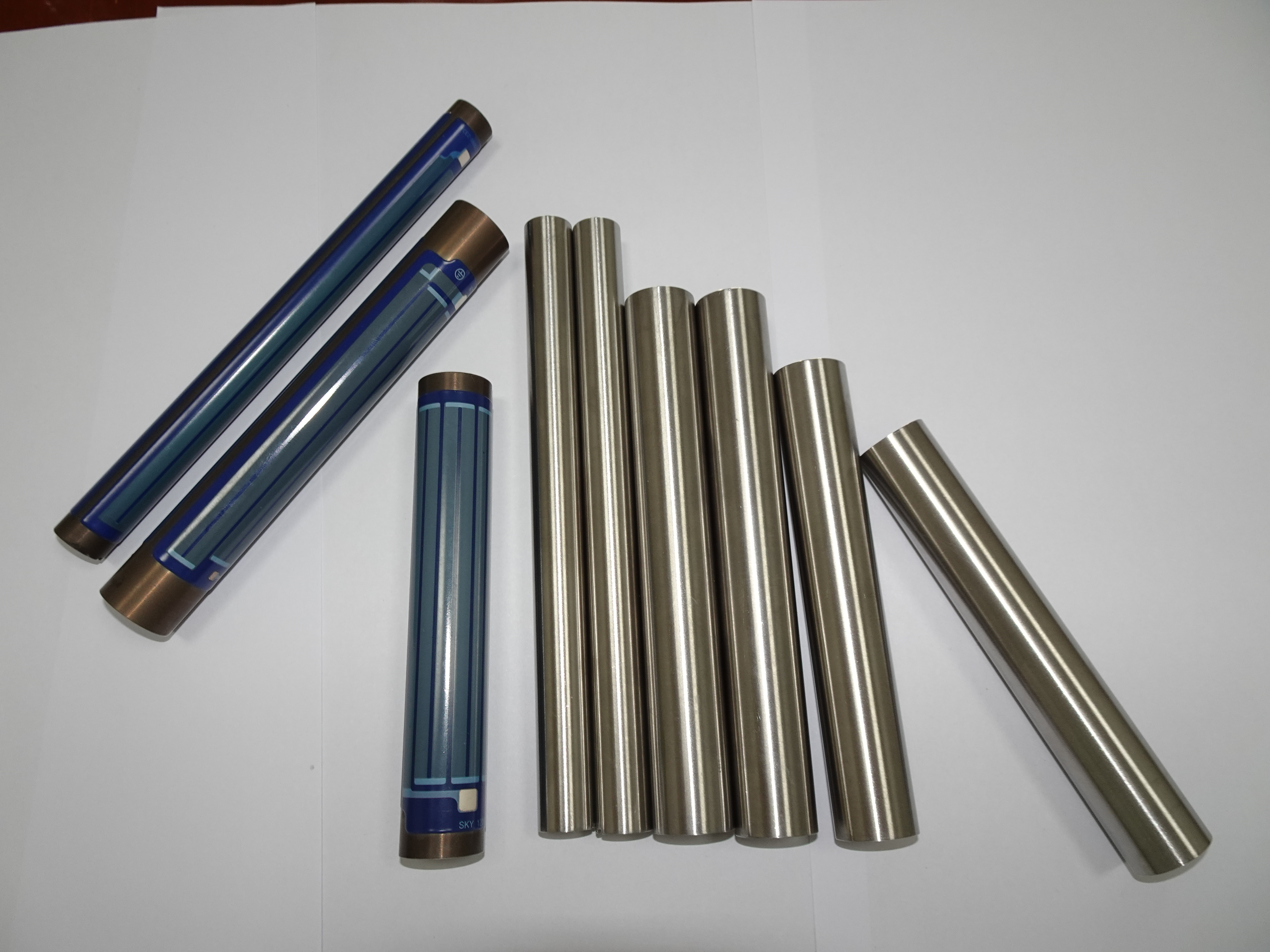

Dynamic blood glucose monitor is an advanced diabetes management tool that monitors blood glucose changes over the next 7 to 14 days by implanting micro sensors under the skin. Its sensor is the most core component with the highest barriers in the system. It consists of metal electrodes, inner layer, enzyme layer and outer membrane, which directly determines the accuracy of the system measurement results. Therefore, the preparation process of its metal electrode is very critical.

The metal electrodes are printed with conductor lines (silver paste, carbon paste) on PI/PET films with a thickness of 50 um to 200 um by screen printing, and the printing accuracy is high. However, this process faces many challenges, and some companies are still struggling to move forward on the R&D road. For example, after printing and drying, the edges of the substrate often lead to deviations in the secondary printing position, affecting the accuracy of the electrode; the substrate itself has large errors, resulting in frequent failure of alignment.

In order to solve these challenges and accelerate the product development process, professional technical support and solutions are needed. Have rich industry experience in dynamic blood glucose monitor electrode printing, and has provided a full set of printing process technology solutions to many companies. At the same time, Oulet also has rich experience in printing processes such as electrode layers, insulating coatings, and enzyme coatings of traditional blood sugar test strips. Let’s take the 40*150mm dynamic blood sugar monitor electrode printing as an example, let’s take a look at how to solve the above challenges.

01 After printing and drying, the substrate is curled, resulting in deviation in secondary printing position

. The machine is equipped with a special adsorption platform to make the substrate firmly fixed on the platform and automatically aligned using the MARK point alignment method to minimize the degree of printing position deviation.

02 The substrate itself has large errors, resulting in frequent alignment failures and other problems.

Optimize the process sequence between the substrate and printing, and reduce the impact of the substrate itself error on printing accuracy.

With the continuous development of technology, dynamic blood sugar monitors will provide more reliable and convenient health management tools for more and more diabetic patients, and the market prospects will be broader. Oulet will continue to deepen its efforts in the field of thick film printing, continuously carry out technological innovation and process optimization and upgrading, actively expand the product line of high-precision thick film printing equipment, provide thick film printing solutions to more industry customers, and jointly promote the vigorous development of related industries.

Home / Products / Why OLAT / Manufacturing / Application / Support / News / Contact Us / privacy policy